|

|

|

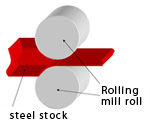

Rolling Rolling |

| Shaping

and deforming materials by passing them through two and more revolving rolls. Depending

on the treating temperature, Classification is made into hot rolling and cold

rolling. |

|

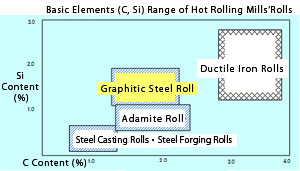

Adamite

Roll Adamite

Roll |

|

Semi-steel base rolls having a high friction coefficient.

A higher friction coefficient improves biting rolled materials. The special

treatment applied can enhance their properties of anti-fire cracking and

toughness. Adamite rolls are applied to billeting mills and rough trains of bar

mills.

|

|

Rolling

mill rolls Rolling

mill rolls |

|

Rolls employed in blast furnace steel

manufacturers and electric furnace steel manufacturers for rolling (the

functions of which are pressing and extending by revolving rolls) steel stock

like slabs and bars. Mechanical properties of steel rolled are drastically

improved. |

|

|

|

|

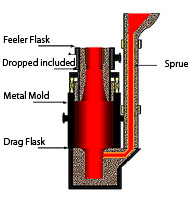

Mold Mold |

| A container that is used to give its shape to molten metal that is poured.

The molds are classified into sand mold, cement mold, metal mold, etc. |

|

Spin Casting (Centrifugal Casting) Spin Casting (Centrifugal Casting) |

| A casting method to pour molten metal into a high speed revolving mold.

The method is classified into vertical method, horizontal method, and inclined

method ( as an intermediate method). |

|

SIP Roll SIP Roll |

Rolls given our original heat treatment performed. SIP comes from “Sumitomo

Improved Penetration.” The finer microstructure in the subsurface zone

and their lower mass effect are realized along with breakage resistance,

anti-surface deterioration and anti-fire cracking improved.

>>Details |

|

Grain Roll (Indefinite Chilled Iron Roll) Grain Roll (Indefinite Chilled Iron Roll) |

Roll material with one of long history. With flaky graphite and cementite

in its microstructure, grain rolls of a high hardness are superior not

only in wear resistance but also in anti-fire cracking, and are usually

applied to the finishing stand of the hot strip mills and pipe rolling

mills.

>>Details |

|

|

|

Graphitic Steel Roll Graphitic Steel Roll |

Semi-steel rolls with small spherical-like graphite precipitated in the

microscopic structure usually applied in order to improve Adamite rolls’

inferior properties of anti-fire cracking and anti-burned sticking.

>>Details |

|

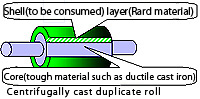

Adjustable Inclined Centrifugal Casting Machine for small size Adjustable Inclined Centrifugal Casting Machine for small size |

Shell melt is poured into the high speed revolving mold at a low inclination

angle setting, and then core melt is poured step by step into the reduced

speed revolving mold at step-by-step further inclination angle settings.

Productivity is improved in comparison with its counterpart (the vertical

method and the horizontal method). The fine microstructure free from the

microscopic dendritic growth generated by vertical method enhances resistance

to fire cracks and surface deterioration. The shell can be produced to

be thicker than the vertical method.

>>Details |

|

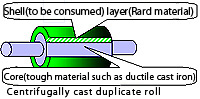

Core Material Core Material |

|

The central cylindrical part of a duplicate roll (the outer part

of a roll barrel is called shell.) The duplicate rolls are conventionally

produced by the centrifugal casting method. The core and the shell are

metallurgically bonded. |

|

|

Static Casting Static Casting |

|

The most common way to pour molten metal into the molds which sit usually

on the bed of a pit. The rolls with a hardness of approximately less than

HSC 70 are cast this way.

>>Details |

|

|

|

|

Ductile Iron Rolls (Spheroidal Graphite Cast Iron Rolls) Ductile Iron Rolls (Spheroidal Graphite Cast Iron Rolls) |

Spheroidal graphite cast iron rolls with spheroidal graphite precipitated

in the matrix of the microscopic structure, excellent in strength and anti-fire

cracking. The applications of ductile iron rolls are extensive, ranging

from slabbing & blooming rolls to finishing train rolls of the wire

rod mills.

>>Details |

|

Iron Base Rolls Iron Base Rolls |

The iron base rolls are divided into grain (indefinite chilled cast iron)

roll, ductile (spheroidal graphite cast) iron roll and definite chilled

cast iron roll. The grain rolls have some flaky graphite in the matrix

of the microscopic structure, the ductile iron rolls some spheroidal graphite,

and the definite chilled cast iron rolls no graphite.

>>Details |

|

|

|

Hot Rolling Hot Rolling |

| Rolling performed above the recrystallization temperature of rolled metal

stock. |

|

High Speed Tool Steel Base Rolls (Sumitomo material code “STZ”) High Speed Tool Steel Base Rolls (Sumitomo material code “STZ”) |

Rolls with intermediate properties between ductile iron rolls and rolls

of semi-steel base like adamite and ordinary high speed tool steel base

rolls. The rolls possess conflicting properties of high resistance to heat

cracking, surface deterioration and high toughness as well as high resistance

to wear.

>>Details |

|

Steel Base(Semi-steel Base) Rolls Steel Base(Semi-steel Base) Rolls |

|

Steel Base(Semi-steel Base) Rolls are classified into Adamite rolls and

graphitic steel rolls. The rolls show a low hardness drop from groove surface

to the cross sectional center and possess a high friction coefficient good

for biting. Good biting is usually required for rolls for slabbing &

blooming mills, billeting mills and the rough train of bar mills, for which

anti-heat cracking properties and high toughness are also required. Steel

base (semi-steel base) rolls applied to the rolled for mills mentioned

above. |

|

|

Centrifugal Casting Composite Rolls Centrifugal Casting Composite Rolls |

|

Rolls manufactured making use of centrifugal force generated by revolving

a mold. A hard material with a high wear resistance is poured for the shell

of roll barrel, and a soft and tough material with a high resistance to

breakage is poured for the core of roll. The interface between the shell

and the core is metallurgically bonded The core is usually of ductile cast

iron with a high strength.

|

|

|

|

|

Cold Rolling Cold Rolling |

| Rolling performed under the recrystallization temperature of rolled metal

stock. |

|

High Speed Tool Steel Base Rolls High Speed Tool Steel Base Rolls |

| Rolls with a higher content of carbon and hard particle forming alloy elements

compared with those of tools of high speed tool steel to improve drastically

resistance to wear and surface deterioration by precipitation of hard carbides

of MC, M2C and M7C3 in the microscopic structure. |

|

|

|