|

|

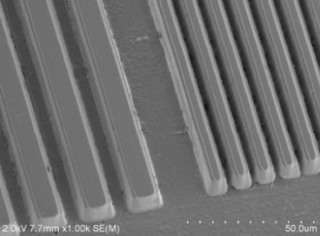

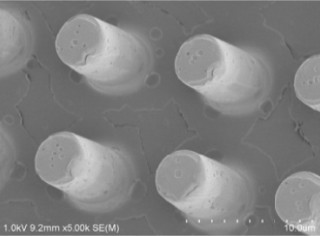

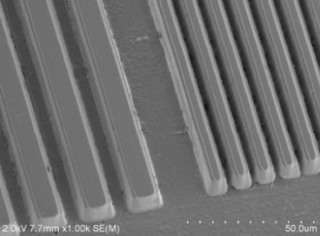

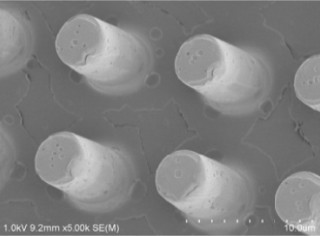

The new molding technology called AMOTEC utilizes CO2 for injection molding in order to achieve fine transcription on plastics. However, since the minimum size of the pattern AMOTEC can replicate is in microns, there is a limit in adopting this technology to nanolevel applications. Therefore we tried to search for alternative approaches and found the press-based imprint technology can give better transcription than other methods. We have obtained the results through the comparative transcription studies, using the imprint system newly developed and the stampers with micro-scale patterns fabricated by synchrotron-radiation-based LIGA technology. In addition, combining a commercially available stamper carrying nano-scale patterns with our imprint system, we could realize pattern transfers of line and space with 100nmpicth and aspect ratio 6. Future developments will be directed to the productivity enhancement through the application of local heating technology to shorten the heat and cool processing time, which so far has been the principal cause of the cycle elongation in the imprint technology.

|

|