|

|

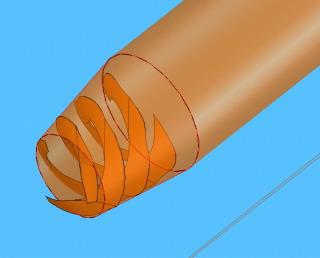

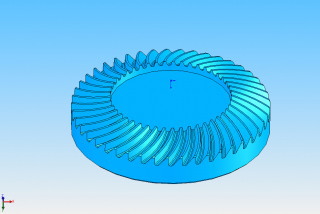

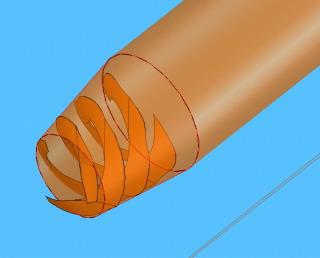

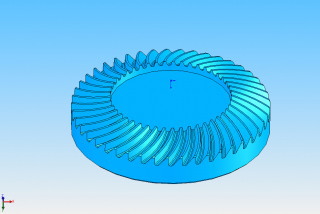

To realize a high performance gear based on designing the unique tooth form of hypoid gears, it is necessary to specify the tooth contact by strictly numerically expressing the gear tooth surface derived from the meshing theory and the tooth surface drawn by the gear-cutting machine or the cutter, which is used to form the gear. Based on the numerically expressed tooth surface form data, we recently developed a program that visualizes the tooth-contact using a tooth-contact analysis method based on numerical analysis and using 3D/CAD software. With this analysis method and program, it is possible to analyze the mechanism of the gear-cutting machine or the cutter specifications through a vector analysis method, and determine the conical axis of the tool in relation to the cradle axis. In addition, they enable us to numerically express the pinion tooth surface based on the simultaneous contact line between the tool cone and the pinion tooth surface, and the gear tooth surface based on the tool cone for gear forming. As we compared the analysis result with the tooth contact of the real product, it has been confirmed that the tooth contact analysis program is valid.

|

|