|

|

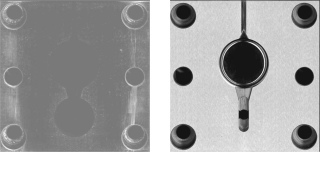

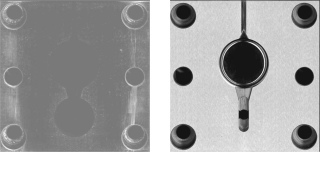

The requirements for injection molding of high performance plastic parts with thinner walls, higher heat resistance, and more complicated shapes have become more demanding. For precision molding, additives in plastic materials, injection at higher temperatures, and more complicated dies have been utilized, but the time between the die maintenances has been shortened due to the vulnerability of forming molding deposits. Various devices have been commercialized to reduce the formation of molding deposits by some manufacturers of injection molding machines and peripheral equipment. Our company is also marketing devices such as ALFIN II and SM screws. The performance evaluation of the devices can be made only after a long field operation, and no quantitative evaluation method is available for an in-house testing made in a short period of time. We have developed a quantitative evaluation method by visualizing the deposits and comparing their digitized shade of color through image data processing. This report presents the evaluation technology and the result of device evaluation.

|

|