|

The Spark Plasma Sintering Process (SPS) has recently attracted

the attention of the powder metallurgy industry. The process sinters

powder metallurgical material packed in a die by applying both pulsed

current and pressure at the same time. The process has several advantages

such as the capability to sinter materials that are difficult to

process with a conventional sintering, the productivity increase

by reduced sintering time, and easy operation by unskilled operators.

We have developed a 500-ton spark plasma-sintering machine and

a rotary-type sintering machine for future business development.

The former has been designed to process large products of a commercial

size, expanding a laboratory device to sinter small size products

for experimental purposes. The latter is a device intended to improve

sintering productivity.

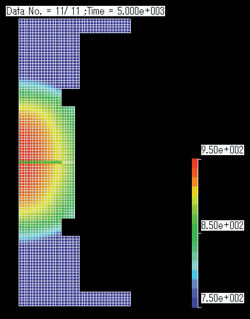

To make high quality products, SPS sintering should be implemented

under uniform temperature and stress. We have developed software

for analyzing the temperature and stress distribution in SPS products

for obtaining optimum sintering conditions. This paper reports the

effectiveness of the software to design dies, comparing the experimental

results and the software predictions.

|