|

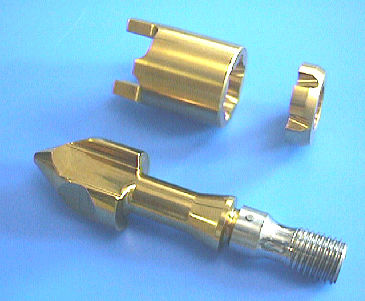

We have developed "SK-control," a new check mechanism for controlling

the reverse flow of molten resin to be injected into a metal mold.

The reverse flow control is an important factor in the injection

process to achieve precise molding in electric injection molding

machines, which have become the main devices replacing hydraulic

driven machines. "SK-control" has a different mechanism from the

conventional one, and has the following features in combination

with the good controllability of electric injection molding machines.

(1) The reverse flow of molten resin is prevented before injection,

to reduce the variation of the reverse flow. Variation is a problem

with conventional check mechanisms.

(2) The new mechanism has eliminated the axial movement of a check

ring for metering resin to be injected. Instead, the check ring

is rotated. The metering is made when a screw is rotated in the

normal direction providing a path for resin flow, and after the

metering the screw is rotated in the reverse direction to close

the flow path.

(3) "SK-control" makes it possible to provide necessary compensation

for changes in resin density.

|