|

|

|

|

|

| gCould the required properties be given only on the limited areas?h SHI Himatex integrates so-far cultivated technologies of casting, building-up, thermal spraying and powder metallurgy and then meets customersf needs by original materials named gSHMh and its unique processing.

Products from SHM series cultivated through application performances and experiences of 15 years realize comfortable working environments.

|

|

|

| If a whole part consists of a single material with high resistances to abrasion, corrosion and/or heat, problems arise like a high part cost or its low machinability (too high cost for machining). It would be very convenient if the required properties can be provided only on the limited areas. Methods invented like nitriding, carbonizing, induction hardening, plating, building-up or thermal spraying are introduced. Each method has insufficient properties such as a low thickness of hardened layer or low resistances to abrasion or spalling. SHM was invented to solve these problems. |

|

|

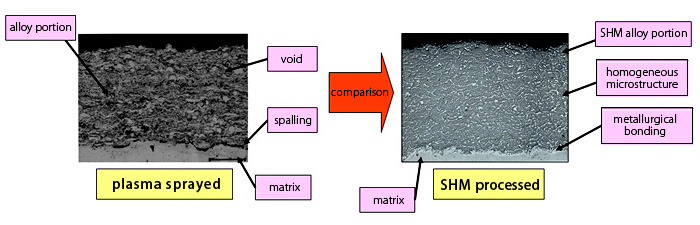

| SHM is a method of lining with SHM alloy of several millimeters thickness limited areas where resistances to abrasion, corrosion and/or sliding are required. There are some general lining methods like TIG building-up, gas building-up, PTA building-up, flame spraying, plasma spraying, or. SHM method is an original processing one. SHM alloy with a tight and uniform microstructure and a high spalling resistant can be deposited on a limited area with selected properties. |

|

|

|

| SHM method is our original processing method to solve problems of void generation within the deposit and spalling of the deposit which are recognized for applications of conventional plasma spraying and latest HVOF (high-velocity flame spraying). SHM alloy of maximum 5 millimeters thickness can be deposited on the selected outer surface where special properties like a high resistance to abrasion and/or corrosion are required. With some fine hard particles added, SHM alloy deposit shows an excellent abrasion resistance. |

|

|

|

|

|

|

|

|

|

|

|

|