|

|

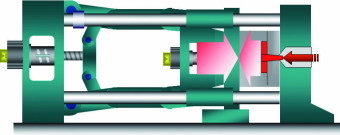

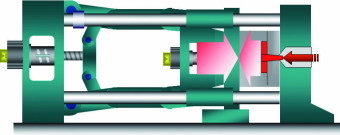

The injection molding process has major problems with metal molds, such as the adhesion of mold deposits and deformation of molds. Lowering the clamping force is one of the methods to reduce these problems. However, since doing so may cause burrs, excessive clamping force is frequently applied in molding, resulting in fracture of the metal mold due to deformation. To improve the technology for reducing the clamping force in molding, a method to detect the lower limit of the clamping force must be developed. Burrs are produced if the mold opening force, which is applied in the direction of opening of the metal mold, rises as a result of increased pressure inside the mold in the cavity to open the mold. In addition, as the pressure inside the mold in the cavity rises, the clamping force follows suit, hence the inferred link between the mold opening force and the clamping force. We recently developed a method for analyzing the dynamic mold opening force by using image processing based on visualization measurement. This paper has analysed the link between the mold opening force and the clamping force, and has verified that it is possible to detect the lower limit of the clamping force to be set by measuring the clamping force.

|

|