|

|

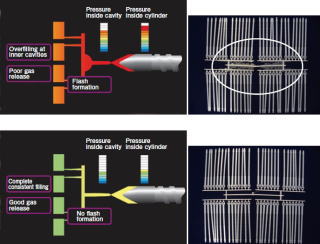

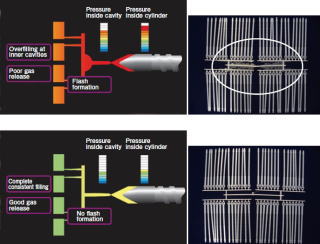

To solve problems (defects, loss and faults) faced daily by mold users on the shop floor, our company recently proposed a molding concept called "Zero-molding system" and a leading-edge molding machine equipped with the same. With the "Flow Front Control (FFC molding)," which is among the Zero-molding system's functions, users can completely fill the metal mold with resin without forcing it into the mold, unlike conventional molding machines. However, the resin flow in this control system has not been sufficiently modeled. For this paper, we prepared an experimental facility of a visualized mold, took photos of the resin flow during FFC molding, and confirmed that this control system was capable of controlling the flow front speed. In addition, we examined the correlation between the resin pressure and the flow front speed, and assuming that the resin would flow using the pressure accumuü╩lated in the resin prior to this control, we modeled this resin flow based on a theoretical formula. By using the latter and flow analysis, this paper discusses why the range of molding conditions for a metal mold with unbalanced filling widens if the FFC molding is used.

|

|