|

|

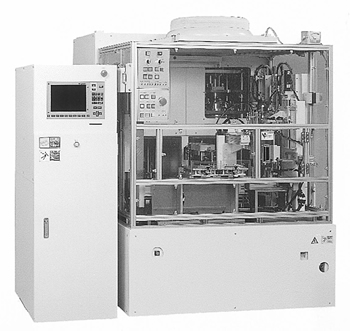

We have developed Sumitomo Micro Molding Device

"NANO-Press", which produces optical elements with

a high degree of accuracy at high throughput by press

molding.

The device has the following features and functions.

1) A newly developed linear pneumatic servo actuator

controls very precisely the position of a molding press

spindle and molding press pressure.

2) Heating and cooling of metal molds are optimized by

infrared heating using a condensing mirror and by a

mold clamping mechanism. Mold temperature is precisely

controlled through a feedback control system.

3) Press molding is done under vacuum as well as an

inert environment.

4) The press molding process is divided into several steps

in order to accommodate a number of metal molds for

enhancing productivity. The metal molds are sequentially

transferred to individual steps.

5) The transfer device of metal molds is standard equip-

ment. It enables an automatic operation to take out

and feed metal molds into or out of individual mold steps

and to pick up vitreous materials. |

|